Solenoid Coils

Solenoid Coils Specification

- Interface

- 2-pin or 3-pin connection

- Output

- Electromagnetic force

- Components

- Coil body, connecting terminals, encapsulation

- Power Supply

- Electric

- Power Source

- Electric

- Thermal Conductivity

- High thermal stability encapsulation

- Input

- 24V DC

- Response Time

- <20 ms

- Operating Temperature

- -10C to +50C

- Usage

- Industrial automation, pneumatic and hydraulic systems

- Features

- Robust construction, high thermal endurance, easy installation

- IP Rating

- IP65

- Product Type

- Solenoid Coil

- Application

- Solenoid valve actuation, machinery control, process automation

- Rated Voltage

- 24V DC

- Supply Voltage

- 24V DC

- Size

- Standard for compatible valves

- Dimension (L*W*H)

- 32 mm x 26 mm x 40 mm

- Function

- Electromagnetic actuation for solenoid valves and devices

- Color

- Black

- Weight

- Approx. 200 grams

- Capacity

- Designed for continuous duty

- Current Rating

- 450 mA

- Thickness

- Standard 18 mm

- Frequency

- DC Operation (50/60 Hz for AC variant)

- Ambient Humidity

- Up to 95% RH (non-condensing)

- Compatibility

- Suitable for various standard solenoid valves

- Dielectric Strength

- 2.5 kV AC for 1 min

- Coil Resistance

- Approx. 53 Ohms at 20°C

- Mounting Type

- DIN Connector or flying leads

- Enclosure Material

- Molded plastic

- Insulation Class

- Class F (155°C)

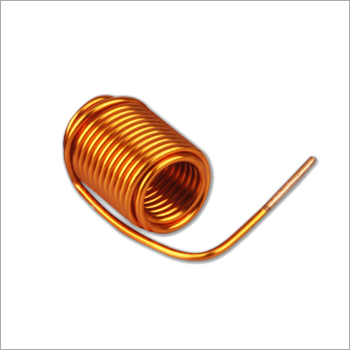

- Core Material

- Copper winding

Solenoid Coils Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About Solenoid Coils

Mulit-Purpose Industrial Application

Designed for integration with solenoid valves and demanding automation processes, this coil is suitable for machinery control, process automation, and pneumatic or hydraulic equipment. Its standard dimensions ensure straightforward replacement or initial assembly in various industrial settings, promoting operational efficiency across sectors.

Durable Construction & High Safety Standards

Built with a molded plastic enclosure and copper winding, the coil offers both high thermal endurance and mechanical resilience. It is rated for ambient humidity up to 95% RH and is protected with Class F insulation, ensuring safe operation even in harsh conditions. An IP65 rating guarantees dust-tight and water-resistant durability.

Quick Installation & Reliable Operation

The coil supports both DIN connector and flying lead configurations, enabling quick, user-friendly installation. With its fast response time of less than 20 ms and stable electromagnetic output, the device ensures precise actuation in automation sequences, contributing to heightened system responsiveness and reliability.

FAQs of Solenoid Coils:

Q: How is the solenoid coil installed and what mounting options are available?

A: The solenoid coil can be easily installed using either a DIN connector or flying leads, depending on your system requirements. This flexibility allows seamless integration into standard solenoid valve assemblies and other industrial automation setups.Q: What advantages does the copper winding and Class F insulation provide?

A: Copper winding ensures efficient electrical conductivity and robust performance, while Class F (155C) insulation delivers high thermal endurance. This combination supports continuous duty operation, even under elevated temperatures, minimizing the risk of coil failure in demanding industrial environments.Q: When should this solenoid coil be used in industrial applications?

A: This coil is especially beneficial for use in machinery control, process automation, pneumatic, and hydraulic systems where reliable electromagnetic actuation of solenoid valves is essential. Its rugged build and rapid response make it suitable for both new installations and replacement in critical operations.Q: Where can the solenoid coil be deployed, considering environmental factors?

A: With an IP65-rated molded plastic enclosure and the ability to operate in up to 95% relative humidity (non-condensing), the coil is ideal for indoor industrial environments exposed to dust or occasional water splashes, ensuring durability in most factory and automation settings.Q: What process is involved in connecting the coil to a power supply?

A: Simply connect the coil to a 24V DC power supply using either two-pin or three-pin interfaces, depending on your configuration. The coil will then convert the supplied electrical energy into electromagnetic force for actuating solenoid valves and other devices.Q: How does this solenoid coil benefit industrial automation systems?

A: Its robust construction, quick response time below 20 ms, and continuous duty cycle ensure dependable performance in fast-paced automation. This reliability translates into reduced downtime, consistent system operation, and enhanced overall process efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Coils Category

Auxiliary Coil

Price Range 80.00 - 400.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Standard/Customized

Components : Copper Wire, Insulation Tape, Bobbin

Interface : Terminal Leads

Rogowski Coils

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Custom Sizes Available (Typical: 150 mm500 mm loop length)

Components : Coil, Integrator (optional)

Interface : Output leads terminated with connectors (optional)

Air Core Coils

Price Range 60.00 - 250.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Size : Varies: 5mm to 50mm Diameter

Components : Copper Wire, Nonmagnetic core (Air)

Interface : Direct Lead or SMD

Coils -

Price 50 INR / Piece

Minimum Order Quantity : 2000 Pieces

Size : Customized

Components : Windings, core

Interface : Terminal Connectors

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS