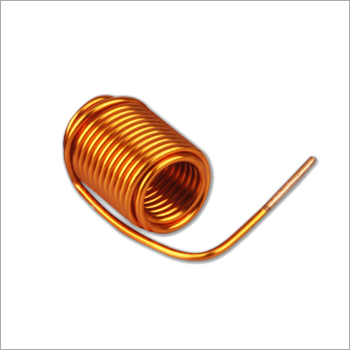

Air Core Coils

Air Core Coils Specification

- Output

- Inductance value

- Power Supply

- Not Applicable (Passive Component)

- Usage

- RF Circuits, Tuners, Filters, Wireless Communication

- Response Time

- Instantaneous

- Features

- High Q factor, Stable performance, Low loss, No core saturation

- Thermal Conductivity

- Non-conductive (Air Core)

- Power Source

- Passive (No external source)

- Operating Temperature

- -40C to +120C

- Components

- Copper Wire, Non-magnetic core (Air)

- Input

- AC/DC (Depends on Design Application)

- Interface

- Direct Lead or SMD

- Product Type

- Air Core Coil / Inductor

- Application

- Electronics, Communication Devices, Radio-frequency Modules

- Rated Voltage

- Up to 250 V

- Size

- Varies: 5mm to 50mm Diameter

- Dimension (L*W*H)

- Customized as per design (e.g., 25mm*10mm*10mm)

- Function

- Inductance in electronic circuits, energy storage in RF and filter applications

- Color

- Copper (Coil), Yellow/Brown (Core)

- Weight

- 2g - 10g (Varies by size)

- Current Rating

- Up to 5A (Varies with design)

- Thickness

- 0.3mm - 1mm (Wire gauge dependent)

- Frequency

- Up to 100 MHz (Typical)

- Environmental Resistance

- Resistant to corrosion and oxidation

- Inductance Range

- Microhenry to millihenry (H to mH)

- Mounting Type

- Through-hole, PCB or free-standing

- Lead Type

- Tinned copper wire leads

- MOQ

- 100 pieces

- Manufacturing Tolerance

- 5% inductance

- Packaging

- Bulk or tray

- Winding Type

- Single layer, multi-turn

- Surface Finishing

- Enamel coated wire

- Coil Shape

- Cylindrical or circular

- Dielectric Strength

- Insulator withstands up to 1kV

- RoHS Compliance

- Yes

- Wire Material

- 99.99% pure copper

Air Core Coils Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Gt Standard or Customized

- Main Domestic Market

- All India

About Air Core Coils

Precision Engineering for Superior Inductance

These air core coils utilize single-layer, multi-turn winding with 99.99% pure copper, maximizing inductive performance and Q factor. Each coil is precisely manufactured, with an inductance tolerance of 5%, and features enamel-coated wire for long-lasting durability. The air (non-magnetic) core ensures theres no core saturation, providing stable and predictable results in signal processing and RF energy storage applications.

Versatile, Durable, and Eco-Friendly Design

Engineered for easy integration, the coils are available in various sizes (5mm50mm diameter) and can be supplied in bulk or tray packaging. Mounting is simplified with tinned copper leads, suitable for both PCB and free-standing configurations. RoHS compliance and resistance to corrosion and oxidation make these coils a sustainable, environment-friendly choice for modern electronics manufacturing.

FAQs of Air Core Coils:

Q: How are these air core coils typically used in electronic circuits?

A: Air core coils are commonly used for inductance in RF circuits, filters, tuners, and wireless communication modules, where stability, high Q factor, and low core losses are essential. Their non-magnetic, air-based core prevents core saturation, making them ideal for high-frequency applications up to 100 MHz.Q: What benefits does the 99.99% pure copper wire offer?

A: Using 99.99% pure copper wire ensures excellent electrical conductivity and minimal signal loss, contributing to a high Q factor and efficient energy transfer. This purity also boosts the coils resistance to corrosion and oxidation, enhancing long-term reliability.Q: Where can these coils be mounted, and what configurations are available?

A: These coils support through-hole mounting directly onto PCBs or can operate free-standing within your circuit. Tinned copper wire leads make installation flexible, and sizes range from 5mm up to 50mm in diameter, with custom dimensions available by design.Q: What is the typical process for integrating these coils into my design?

A: Integration involves selecting the appropriate coil size and inductance value that fits your circuits requirements. The tinned leads can be easily soldered onto a PCB or used for free-standing setups. Bulk or tray packaging supports both prototype and mass production workflows.Q: When should I choose an air core coil versus a magnetic core coil?

A: Choose air core coils when you need high frequency operation, minimal core losses, instant response, and immunity to core saturation ideal for RF, filters, and wireless communication circuits. For low-frequency, high-inductance needs, magnetic core coils may be more suitable.Q: What are the environmental and safety features of these coils?

A: The coils are RoHS compliant, using environmentally safe materials. An enamel coating on the wire and a corrosion-resistant design enhance durability. The insulator withstands up to 1kV dielectric strength, and the coils operate reliably from -40C to +120C.Q: What are the minimum order quantities and customization options?

A: The minimum order quantity is 100 pieces, and custom sizes, shapes, and inductance ranges can be tailored to your design specifications. Packaging is available as bulk or tray to suit both small and large-scale operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Coils Category

Rogowski Coils

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

IP Rating : IP54

Usage : Measurement of AC Current, Power Monitoring, Harmonic Analysis

Response Time : < 1 s

Auxiliary Coil

Price Range 80.00 - 400.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

IP Rating : IP20

Usage : Control Panels, Switchgear, Relays

Response Time : Instantaneous (Relay Actuation)

Solenoid Coils

Price Range 80.00 - 400.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

IP Rating : IP65

Usage : Industrial automation, pneumatic and hydraulic systems

Response Time : <20 ms

Coils -

Price 50 INR / Piece

Minimum Order Quantity : 2000 Pieces

IP Rating : IP20

Usage : Electrical applications, transformers, relays

Response Time : Instantaneous

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS