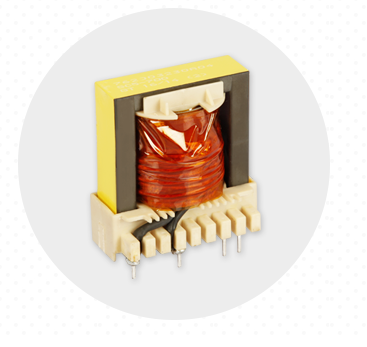

Special Customized Transformer

Special Customized Transformer Specification

- Capacity

- Customized (up to 3000 kVA)

- Cooling Type

- ONAN / ONAF / Air Cooled / Oil Cooled

- Operating Temperature

- -25C to +50C

- Low Voltage

- Customized (as per requirement)

- Load Loss

- Low, as per IEC/IS standards

- Rated Voltage

- Up to 33 kV

- Dimension (L*W*H)

- Customized as per order specification

- Voltage Booster Type

- Step-Up / Step-Down / Booster (Customizable)

- Coil Material

- High Purity Copper / Aluminum (as required)

- High Voltage

- Customized (typically up to 33 kV)

- Standard

- IS 2026 / IEC 60076 / Customized Standards

- Product Type

- Special Customized Transformer

- Material

- Copper Winding, Laminated Silicon Steel Core

- Output

- Custom Output Voltage as per client need

- Frequency (MHz)

- 50-60 (Typical)

- Efficiency

- 98%

- Phase

- Single Phase / Three Phase (As per requirement)

- Usage

- Industrial Electrical Applications, Custom Electrical Systems

- Coil Structure

- Toroidal / Shell / Core (Customizable)

- Coil Number

- As per custom design

- Power Scope

- Up to 3000 kVA or customized

- Weight

- Depends on design specification (Approx. 200 kg and above)

Special Customized Transformer Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About Special Customized Transformer

Advanced Features & Versatility

The Special Customized Transformer is distinguished by a suite of advanced features, including customizable coil structures (toroidal, shell, or core), high-purity copper or aluminum windings, and an array of mounting and enclosure options. Renowned for reliability, its expertly suited for powering industrial facilities, custom electrical systems, and voltage regulation tasks. Its operating temperatures range from -25C to +50C, and its efficiencytypically 98%ensures minimal energy loss with every use.

International Markets & Seamless Transactions

This products main domestic market is India, with thriving export activity to regions such as the Middle East, Africa, and Southeast Asia. Sale price varies depending on specifications and customization level. Each transformer is securely packaged for safe transport and is handed over either at the factory or port, as per client requirements. Payment terms are flexibleoptions include advance, letter of credit, or other mutually agreed methods, supporting a risk-free purchasing experience.

FAQs of Special Customized Transformer:

Q: How do I choose the right transformer configuration for my application?

A: You can select the winding connection (Delta/Star), mounting style, and output voltage based on your specific operational requirements. Our technical experts will assist you in deciding the best configuration for your needs.Q: What features make this transformer suitable for industrial use?

A: Its high efficiency (98%), custom output voltage, robust epoxy-coated enclosure, and low noise level make it ideal for demanding industrial environments with strict reliability and safety standards.Q: Where can the Special Customized Transformer be shipped?

A: We offer seamless shipment across India and export to international markets including the Middle East, Africa, and Southeast Asia.Q: What is the process for ordering a customized transformer?

A: After initial consultation, our team evaluates your requirements, recommends design options, shares technical drawings, and upon approval, proceeds with manufacturing and rigorous IEC-compliant testing before delivery.Q: What is the benefit of the manufacturer warranty provided?

A: The 12-24 months manufacturer warranty guarantees free repair or replacement for defects under normal use, ensuring long-term peace of mind and operational continuity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

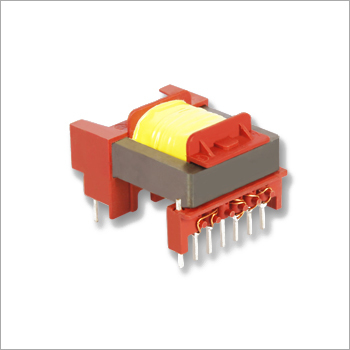

More Products in High Frequency Transformer Category

Push-Pull Transformer

Price Range 120.00 - 400.00 INR / Piece

Minimum Order Quantity : 2000 Pieces

Dimension (L*W*H) : Custom or Standard Models (e.g. 75 x 55 x 45 mm)

Power Scope : 10W 1000W

Material : Copper Wire, Ferrite Core

Encapsulated Current Transformer

Price 150-2000 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : Custom/Standard as per model (refer to datasheet)

Power Scope : 66 kV and below (upto standard ratings)

Material : Epoxy Resin Encapsulated, Copper windings, Highgrade silicon steel

Forward Transformer

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : 1100 mm x 700 mm x 1350 mm

Power Scope : Up to 200 kVA

Material : Copper and Silicon Steel

HF Transformer

Price 500 INR / Piece

Minimum Order Quantity : 500 Pieces

Dimension (L*W*H) : Varies with model (Typical: 45x40x35 mm to 170x110x90 mm)

Power Scope : 10W 5000W

Material : Ferrite Core, Copper Winding

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS