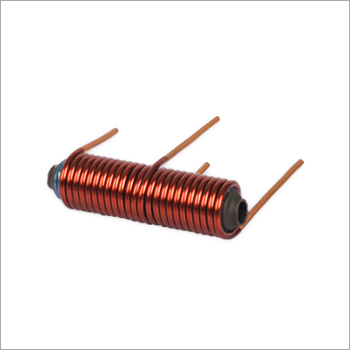

Rod Core - Drum Core Inductor

Rod Core - Drum Core Inductor Specification

- Power Source

- Not Applicable (Passive component)

- Features

- Low loss, High reliability, Shielded versions available, Compact size

- Response Time

- Immediate (Passive component)

- Operating Temperature

- -40C to +125C

- Usage

- Power Supply Filters, EMI Suppression, DC-DC Converters

- Interface

- Wire lead or SMD

- IP Rating

- Not Rated

- Power Supply

- Not Applicable (Passive Component)

- Components

- Ferrite rod core, enameled copper wire

- Product Type

- Rod Core Drum Core Inductor

- Application

- Switching power supplies, Noise filtering, Power amplifiers, Signal processing

- Rated Voltage

- 250V

- Supply Voltage

- Up to 250V

- Size

- Varies by model (e.g., 8x10mm, 10x12mm)

- Dimension (L*W*H)

- Commonly 10mm 10mm 12mm (can vary)

- Function

- Inductance / Energy Storage

- Color

- Black body with copper winding

- Weight

- Approx. 1-3g (varies on size)

- Current Rating

- Up to 3A (varies as per specification)

- Capacity

- Inductance rating varies (e.g., 10uH to 1mH)

- Thickness

- Varies by model, typically 4mm to 20mm

- Frequency

- DC to 500kHz (dependent on application)

Rod Core - Drum Core Inductor Trade Information

- Minimum Order Quantity

- 2000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About Rod Core - Drum Core Inductor

Versatile and Reliable Inductors

Rod Core - Drum Core Inductors, designed with ferrite cores and offered in various configurations, provide robust performance for demanding electronic applications. Their multiple mounting and packaging options make them well-suited for diverse circuit designs, including power supply filters and EMI suppression. The epoxy coating and RoHS compliance ensure durability and environmental safety, while low DC resistance and high inductance stability enhance overall efficiency. They comply with international standards, giving engineers confidence in every unit deployed.

Wide Application Range

These inductors are essential components in switching power supplies, noise filtering circuits, power amplifiers, and general signal processing. With inductance values from 10uH up to 1mH and current ratings reaching 3A, their compact black body and copper winding deliver optimal performance for both low- and high-frequency operations up to 500kHz. Available with either wire lead or SMD interface, they offer engineers significant flexibility for both design and manufacturing processes.

FAQs of Rod Core - Drum Core Inductor:

Q: How should I select the appropriate Rod Core - Drum Core Inductor for my application?

A: Consider your circuits desired inductance, current rating, and mounting requirements. Assess available variants for inductance value (e.g., 10uH to 1mH), current handling (up to 3A), physical size, and whether you need through-hole or surface mount compatibility. Refer to product datasheets for exact dimensions and electrical parameters suitable for power supply, EMI suppression, or signal processing.Q: What are the main benefits of using a ferrite core in these inductors?

A: Ferrite cores provide high efficiency, low energy loss, and stable inductance across a broad frequency spectrum. This makes them ideal for noise filtering and power supply applications, especially in circuits operating up to 500kHz. Additionally, ferrite cores help maintain compact component dimensions while supporting high current ratings.Q: When is it recommended to use the shielded version of this inductor?

A: Shielded versions are recommended in applications where electromagnetic interference (EMI) must be minimizedsuch as sensitive signal paths, high-frequency switching regulators, and equipment conforming to stringent EMI standards. Shielding helps reduce radiated noise and improves overall circuit reliability.Q: Where can I typically use Rod Core - Drum Core Inductors in electronic designs?

A: These inductors are widely utilized in power supply filters, EMI suppression circuits, DC-DC converters, switching power supplies, power amplifiers, and signal processing modules. Their diverse range of sizes and electrical characteristics fits many general-purpose and specialized electronic systems.Q: What is the typical process for installing these inductors on a PCB?

A: For through-hole types, insert the leads into designated PCB holes and solder. For surface mount models, place the SMD component onto solder-pasted pads and reflow solder. Ensure the correct orientation and good solder joints for reliable electrical and mechanical connection.Q: How does the inductors inductance tolerance affect circuit performance?

A: Inductance tolerance of 10% or 20% indicates potential variation from the stated value. Precise tolerance is critical in frequency-sensitive circuits, such as resonant filters or oscillators, where consistent inductive values affect signal behavior and efficiency.Q: What are the key features that make these inductors suitable for export or large-scale supply?

A: With robust construction, RoHS compliance, international standard adherence, and various packaging options (bulk or tape & reel), these inductors are manufactured for quality, consistency, and ease of integration across global markets. Their compact size, reliability, and adaptability support both OEM and mass production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inductor and Chokes Category

Power Factor Correction Chokes (PFC)

Price 00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Weight : Approx. 615 kg (varies by capacity)

Product Type : Power Factor Correction Choke

Thickness : Core thickness varies; typically 4060 mm

Storage Chokes

Price Range 120.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Weight : Approx. 2 Kg

Product Type : Storage Choke

Thickness : 40 mm (Core thickness)

Choke Coil

Price 500 INR / Piece

Minimum Order Quantity : 500 Pieces

Weight : Approx 120 g

Product Type : Choke Coil

Thickness : 8 mm (wire gauge varies)

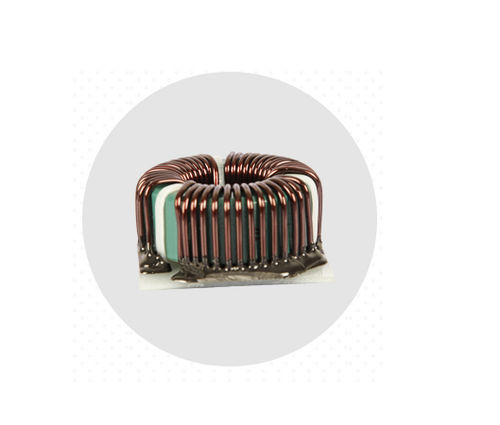

Toroidal Choke

Price 300 INR / Piece

Minimum Order Quantity : 500 Pieces

Weight : 42 grams

Product Type : Toroidal Choke

Thickness : 8 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS