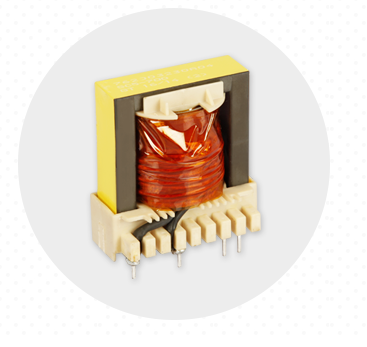

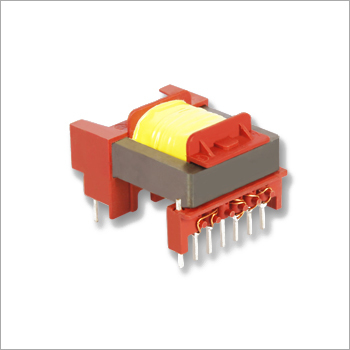

High Frequency Transformer

Price 500 INR/ Piece

High Frequency Transformer Specification

- Standard

- IEC 60076, RoHS compliant

- Low Voltage

- 5 V 220 V

- Operating Temperature

- -25C to +85C

- Coil Material

- 99.9% Pure Copper

- Voltage Booster Type

- Step-Up / Step-Down

- Cooling Type

- Natural Air / Forced Air

- Load Loss

- Minimal (< 1%)

- Dimension (L*W*H)

- 48 x 40 x 40 mm (standard); Custom sizes available

- Rated Voltage

- Up to 1000 V

- High Voltage

- 600 V 1000 V

- Capacity

- 300 VA 20,000 VA

- Product Type

- High Frequency Transformer

- Material

- Ferrite Core, Copper Winding

- Output

- AC / DC (As Required)

- Frequency (MHz)

- 20 - 500 kHz

- Efficiency

- 98%

- Phase

- Single Phase / Three Phase

- Usage

- Power Conversion, Electronic Devices, LED Lighting, Switching Power Supplies

- Coil Structure

- Toroidal / E-Core / Encapsulated

- Coil Number

- Dual/Multiple Windings

- Power Scope

- Up to 20 kW (customizable)

- Weight

- 150 g - 5 kg (as per model)

- Applications

- SMPS, Inverters, UPS, Medical Equipment, Industrial Electronics

- Core Shape

- E, EE, EI, PQ, RM, U Core

- Mounting Type

- PCB Mount / Chassis Mount

- Customization

- Available on Request

- Surface Finish

- Epoxy Coated / Enclosed

- Flammability Rating

- UL94V-0

- Isolation Resistance

- > 100 M

- Insulation Class

- Class F / H

- Dielectric Strength

- Up to 3500 V AC

- Winding Technique

- Layer, Section or Bifilar as specified

About High Frequency Transformer

GT Electronic India designs and manufactures all kind of customized high frequency switching transformers in various geometry like EE, EF, ETD, EFD, RM, PQ, EI, ER,EP and toroidal. The operation frequency range is up to 200KHz.Versatile and Customizable Solutions

Our high frequency transformers can be tailored to meet your specific requirements, offering a broad range of input/output voltages and power capacities up to 20 kW. From standard dimensions (48 x 40 x 40 mm) to entirely custom designs, we cater to diverse project needs, whether for compact electronics or industrial-scale systems.

Enhanced Safety and Compliance

Prioritizing operational safety, these transformers are built with insulation classes F or H and dielectric strength up to 3500 V AC. Engineered to comply with IEC 60076 and RoHS, and utilizing flame-retardant materials rated UL94V-0, they deliver exceptional electrical isolation and robust fire protection for peace of mind in critical environments.

Efficient Performance, Reliable Usage

Designed for high efficiency (98%) and minimal load loss (<1%), our transformers are ideal for power conversion in electronic devices, switching power supplies, and LED lighting. Operating across a wide temperature range and supporting both natural and forced air cooling, they maintain stable performance even in demanding settings.

FAQ's of High Frequency Transformer:

Q: How does the high frequency transformer ensure electrical safety and insulation?

A: The transformer offers insulation classes F and H, dielectric strength up to 3500 V AC, and isolation resistance exceeding 100 M. Flame resistance (UL94V-0) and robust epoxy or enclosed finishes further enhance safety, making it suitable for high-voltage and critical applications.Q: What customization options are available for these transformers?

A: Customization includes core shape, winding technique (layer, section, or bifilar), voltage output (5 V - 1000 V), frequency (20 - 500 kHz), coil structure, mounting type, power capacity (up to 20 kW), and dimensions. Additional options can be provided to suit unique industry requirements.Q: When should I choose a PCB mount versus a chassis mount transformer?

A: Choose PCB mount designs for compact, board-level integration in electronic devices. Chassis mount varieties are preferred for larger or more robust systems such as industrial equipment, inverters, or UPS units, where physical and electrical stability are critical.Q: Where can these transformers be effectively used?

A: They are designed for switching power supplies, LED lighting, power conversion, SMPS, medical equipment, inverters, UPS, and industrial electronics. They are suitable for both commercial electronic devices and heavy-duty industrial applications.Q: What are the key benefits of using these high frequency transformers?

A: Users benefit from exceptional efficiency (98%), minimal load loss, wide operating temperature range, and adaptability for single or three phase systems. Their high voltage rating, reliable insulation, and UL-certified safety features ensure long-term performance and protection for sensitive loads.Q: How are these transformers manufactured and tested for quality?

A: Manufacturing follows IEC 60076 and RoHS guidelines, with rigorous quality controls, testing for dielectric strength, isolation resistance, and thermal stability. Materials include ferrite cores and 99.9% pure copper windings to ensure reliability and compliance.Q: What is the process for requesting a customized transformer solution?

A: To request customization, provide specifications such as input/output voltage, frequency, power scope, mounting type, and application details. Our engineering team will design and manufacture a transformer tailored to your project, ensuring optimal performance and full standards compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Frequency Transformer Category

SMPS Transformer

Price Range 120.00 - 500.00 INR / Piece

Price nan INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Ferrite Core, Copper Windings

Low Voltage : As per output specification

Product Type : Other, SMPS Transformer

Push-Pull Transformer

Price Range 120.00 - 400.00 INR / Piece

Minimum Order Quantity : 2000 Pieces

Material : Copper Wire, Ferrite Core

Low Voltage : 1.5V 48V

Product Type : Other, PushPull Transformer

Encapsulated Current Transformer

Price 150-2000 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Epoxy Resin Encapsulated, Copper windings, Highgrade silicon steel

Low Voltage : Secondary: 1A / 5A

Product Type : Other, Encapsulated Current Transformer

Forward Transformer

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Copper and Silicon Steel

Low Voltage : 415 V

Product Type : Other, Forward Transformer

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS