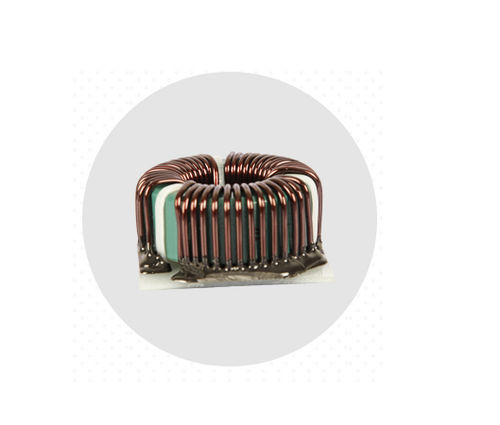

Current Compensated Suppression Choke

Price 00 INR/ Piece

Current Compensated Suppression Choke Specification

- Power Source

- Inline passive component

- Output

- Filtered AC Current

- Usage

- Electromagnetic noise suppression in electronic circuits

- Power Supply

- AC

- Features

- Low leakage current, compact design, easy PCB mounting

- Interface

- Wire terminal connection

- Input

- AC Current

- Operating Temperature

- -25C to +85C

- Components

- Ferrite core, copper wire, insulating material

- IP Rating

- IP00

- Product Type

- Current Compensated Suppression Choke

- Application

- Power supplies, electronic equipment, household appliances, industrial electronics

- Rated Voltage

- 250V AC

- Supply Voltage

- 110-250V AC

- Size

- Ring core diameter 18 mm

- Dimension (L*W*H)

- 20 mm x 16 mm x 25 mm

- Function

- Current compensation and suppression of EMI (Electromagnetic Interference)

- Color

- Black with Copper windings

- Weight

- Approx. 40g

- Capacity

- 3A continuous current

- Thickness

- 10 mm

- Current Rating

- 3A

- Frequency

- 50/60 Hz

- RoHS Compliance

- Yes

- Contact Resistance

- <10 m

- Standards Compliance

- IEC 60938-2

- Dielectric Strength

- 1500V AC for 1 minute

- Inductance

- 2 x 3.7 mH

- Core Material

- High-permeability Ferrite

- Leakage Current

- 0.2 mA at rated voltage

- Mounting Type

- Through Hole

- Insulation Resistance

- >100 M at 500V DC

- Climatic Category

- 25/085/21

Current Compensated Suppression Choke Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About Current Compensated Suppression Choke

Efficient EMI Noise Suppression

Designed for electromagnetic interference reduction, this suppression choke provides reliable current compensation, making it ideal for sensitive electronic applications. Its high permeability ferrite core and copper windings ensure effective filtering in power supplies, household devices, and industrial electronics, safeguarding circuit operation.

Durable Construction and Mounting Flexibility

With a robust through-hole mounting system and quality insulating materials, this choke guarantees longevity under demanding conditions. Compact dimensions and straightforward wire terminal connections support easy installation on printed circuit boards, enhancing design flexibility for engineers and manufacturers alike.

Compliant and Reliable for Global Standards

Fully compliant with IEC 60938-2 and RoHS directives, this component offers international reliability and safety. High insulation resistance, low leakage current, and strong dielectric strength ensure operational integrity, making it suitable for both domestic and export-oriented electronic projects.

FAQs of Current Compensated Suppression Choke:

Q: How does the current compensated suppression choke suppress electromagnetic interference (EMI) in electronic circuits?

A: The choke utilizes a high-permeability ferrite core and dual windings to create opposing magnetic fields for in-phase currents, effectively canceling noise and suppressing EMI. This ensures that unwanted high-frequency signals are filtered out while allowing desired AC current to flow through.Q: What applications are suitable for this suppression choke?

A: This component is ideal for use in power supplies, household appliances, and industrial electronics that require electromagnetic noise suppression. It fits both commercial and domestic projects where reliable AC line filtering is necessary, thanks to its 3A current rating and wide supply voltage (110250V AC) compatibility.Q: Where should this suppression choke be mounted within an electronic system?

A: Mount the choke at the input stage of your power supply or AC line, directly onto the printed circuit board using the through-hole terminals. Its compact size and wire terminal connections facilitate straightforward insertion into a variety of PCB layouts.Q: What is the process for installing this choke on a PCB?

A: Begin by locating the input section designated for EMI filtration. Insert the choke into the appropriate through-hole connectors, ensuring secure wire terminal contact. Solder the leads onto the PCB and confirm the insulation and orientation before powering the system.Q: What are the key benefits of using this suppression choke over standard inductors?

A: Compared to standard inductors, this suppression choke provides superior EMI attenuation due to its current compensated design and high-permeability ferrite core. It delivers low leakage current, high insulation resistance, compact form factor, and meets stringent international safety and environmental standards.Q: When should this choke be selected in a power supply design?

A: Select this choke during the initial stages of designing AC-powered equipment that requires minimized EMI, particularly when adhering to international compliance standards. It is especially beneficial for devices operating within 25C to +85C, with 3A continuous current and up to 250V AC supply.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inductor and Chokes Category

Storage Chokes

Minimum Order Quantity : 1000 Pieces

Usage : Electrical and electronic applications

Product Type : Storage Choke

Power Supply : AC

Size : Custom as per requirement

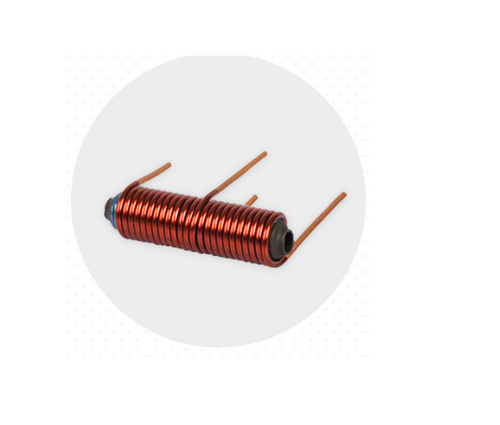

Choke Coil

Price 500 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Electronic circuits, Power supplies, Industrial devices

Product Type : Choke Coil

Power Supply : AC / DC

Size : Standard size (customizable)

Inductor Coil

Price 500 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Electronic Circuitry

Product Type : Inductor Coil

Power Supply : AC/DC

Size : Medium

Drum Core Inductor

Price 75 INR / Piece

Minimum Order Quantity : 2000 Pieces

Usage : Electronic circuits

Product Type : Drum Core Inductor

Power Supply : DC

Size : Common sizes: 3x3 mm, 4x4 mm, 6x6 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS