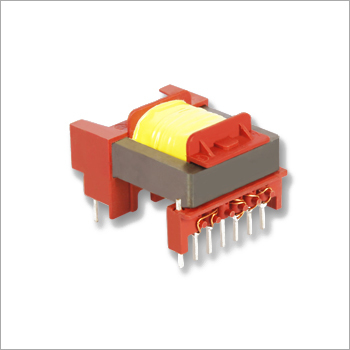

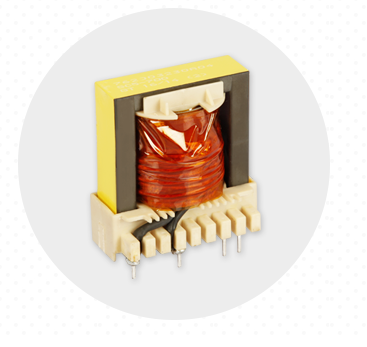

HF Transformer

Price 500 INR/ Piece

HF Transformer Specification

- Capacity

- Customizable as per application

- Load Loss

- 3%

- Low Voltage

- 1V 48V

- Dimension (L*W*H)

- Varies with model (Typical: 45x40x35 mm to 170x110x90 mm)

- Coil Material

- Pure Copper / Copper Alloy

- Rated Voltage

- 110V 380V AC

- Voltage Booster Type

- Step Up / Step Down

- Cooling Type

- Air Cooled / Natural Convection

- High Voltage

- Up to 5kV

- Standard

- IEC 61558, RoHS Compliant

- Operating Temperature

- 40C to +125C

- Product Type

- HF (High Frequency) Transformer

- Material

- Ferrite Core, Copper Winding

- Output

- Multiple Secondary Outputs, Customizable

- Frequency (MHz)

- 40 100 MHz

- Efficiency

- Up to 98%

- Phase

- Single Phase / Three Phase

- Usage

- Switching Power Supplies, LED Drivers, SMPS, Power Electronics

- Coil Structure

- Toroidal / EI / Custom

- Coil Number

- Dual / Multi-coil

- Power Scope

- 10W 5000W

- Weight

- 0.2 kg 5 kg (Depending on model)

- Storage Temperature

- 55C to +150C

- Vibration Resistance

- 10500 Hz, 5 g

- Winding Method

- Layer wound/Bifilar/Triple insulated

- Relative Humidity

- 95% (non-condensing)

- Mounting Type

- Through-Hole / PCB Mountable

- Insulation Resistance

- >1000 M at 500V DC

- Primary to Secondary Isolation

- >2 M

- Dielectric Strength

- 2500V AC for 1 min

- Core Type

- EE/EI/ETD/Toroidal/Ferrite Core

- Flame Retardant Grade

- UL 94V-0

- Typical Applications

- Switch Mode Power Supply (SMPS), Medical Devices, Industrial Controls, Communication Equipment

- Environmental Compliance

- Halogen Free, Lead Free (Pb-Free)

About HF Transformer

GT Electronic India designs and manufactures all kind of customized high frequency switching transformers in various geometry like EE, EF, ETD, EFD, RM, PQ, EI, ER,EP and toroidal. The operation frequency range is up to 200KHz.Superior Electrical and Mechanical Properties

Engineered for quality and safety, the HF Transformer offers high dielectric strength (2500V AC for 1 min) and robust insulation resistance (>1000 M at 500V DC). Its vibration resistance (10-500 Hz, 5 g), broad storage and operating temperature range, and flame-retardant casing (UL 94V-0) suit demanding installations. Advanced winding methods such as bifilar and triple-insulated winding further enhance performance and longevity.

Custom Solutions for Diverse Applications

With compatibility across EE, EI, ETD, Toroidal, and Ferrite core types, the HF Transformer can be tailored for use in SMPS, LED drivers, power electronics, industrial systems, and medical devices. Customizable voltage, power ratings (10W-5000W), coil structures, and outputs make it adaptable for single or three-phase operations and unique customer needs.

Eco-Friendly and Compliant Design

The HF Transformer stands out with its lead-free, halogen-free build, and compliance with IEC 61558 and RoHS directives. These features make it a safe, eco-conscious option for global markets, while maintaining efficient performance and reliability in critical equipment.

FAQ's of HF Transformer:

Q: How is the dielectric strength of the HF Transformer significant for safety?

A: The HF Transformer provides a high dielectric strength of 2500V AC for 1 minute, ensuring effective isolation between windings. This minimizes the risk of electrical breakdown, making the transformer especially suited for safety-critical environments like medical devices and industrial controls.Q: What mounting options are available for this transformer and where can it be installed?

A: The HF Transformer features through-hole and PCB-mountable designs, allowing flexible installation on various printed circuit boards or enclosures. This makes it suitable for integration in switch mode power supplies, LED drivers, and communication equipment.Q: When should I choose bifilar or triple insulated winding methods for my application?

A: Bifilar or triple insulated windings are recommended when enhanced insulation, reduced leakage inductance, or added safety layers are required. These winding methods are especially beneficial in high-frequency or high-voltage applications and where IEC 61558 compliance is necessary.Q: Which environmental standards does the HF Transformer comply with?

A: The transformer is RoHS compliant, halogen-free, lead-free (Pb-Free), and meets the IEC 61558 standard. Additionally, its UL 94V-0 flame retardant rating ensures suitability for global and environmentally sensitive applications.Q: How does the customizable power scope and output benefit users?

A: Customizability in power ratings (10W to 5000W), multiple secondary outputs, and coil configurations allow the HF Transformer to be precisely tailored to application-specific needs. This flexibility enhances performance and ensures optimal integration across diverse industries.Q: What are the process steps for ordering a custom HF Transformer?

A: To order a custom HF Transformer, specify application requirements such as voltage, power, core type, output configuration, and mounting preference. The manufacturer will collaborate with you to design, prototype, and manufacture the solution tailored to your technical and compliance needs.Q: What advantages does the HF Transformer offer for industrial and medical applications?

A: Thanks to its high insulation resistance, flame retardant materials, robust mechanical design, and compliance with safety standards, the HF Transformer delivers reliable, efficient performance. Its adaptability makes it an excellent choice for sensitive equipment in medical and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Frequency Transformer Category

SMPS Transformer

Price nan INR / Piece

Price Range 120.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Output : 12V/24V/48V (customizable)

Load Loss : <1%

Capacity : Custom as per design

Forward Transformer

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Output : Electrical Power

Load Loss : 540 W

Capacity : 150 kVA

Push-Pull Transformer

Price Range 120.00 - 400.00 INR / Piece

Minimum Order Quantity : 2000 Pieces

Output : Dual or Multiple Outputs

Load Loss : < 3%

Capacity : As per Design Specification

Special Customized Transformer

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Output : Custom Output Voltage as per client need

Load Loss : Low, as per IEC/IS standards

Capacity : Customized (up to 3000 kVA)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS