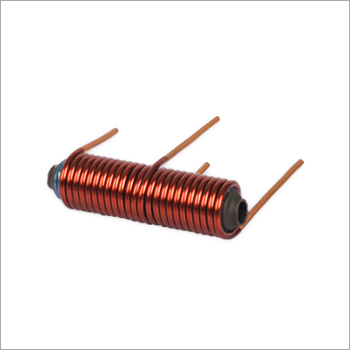

Power Factor Correction Chokes (PFC)

Price 00 INR/ Piece

MOQ : 1000 Pieces

Power Factor Correction Chokes (PFC) Specification

- Features

- Low losses, high reliability, long life, minimal noise

- Response Time

- Instantaneous

- Usage

- Power factor correction for industrial applications

- Components

- Copper/aluminum windings, laminated core, terminal blocks

- IP Rating

- IP00

- Interface

- Screw terminal connection

- Power Source

- AC Power

- Output

- Enhanced power factor, reduced harmonics

- Power Supply

- Three phase AC

- Input

- AC Voltage input, 50 Hz

- Operating Temperature

- -10C to 45C

- Product Type

- Power Factor Correction Choke

- Application

- Electrical panels, capacitor banks, PFC systems

- Rated Voltage

- 415 V AC

- Supply Voltage

- 415 V AC

- Size

- Custom as per power rating

- Dimension (L*W*H)

- Approx. 250mm x 110mm x 160mm (varies by rating)

- Function

- Improves power factor and filters harmonics in AC circuits

- Color

- Copper (Winding), Black (Core)

- Weight

- Approx. 6-15 kg (varies by capacity)

- Current Rating

- 10A to 60A (depending on model)

- Thickness

- Core thickness varies; typically 40-60 mm

- Capacity

- 6 KVAR to 50 KVAR

- Frequency

- 50 Hz

Power Factor Correction Chokes (PFC) Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About Power Factor Correction Chokes (PFC)

Incepted as a leading company, we are able to manufacture, export and supply Power Factor Correction Chokes (PFC). The offered choke is made in accordance with international quality standards using premium grade basic materials with the help of ultra-contemporary techniques. It is mainly used for offering power supply to domestic RO system. Also, our customers can avail the offered Power Factor Correction Chokes (PFC) at the most reasonable prices from us within the promised time span.

Optimized Performance in Industrial Settings

These PFC chokes are tailored for seamless integration into industrial environments, supporting heavy-duty power factor correction and harmonic suppression. The use of high-quality copper windings and CRGO steel cores ensures minimal loss and reliable performance under demanding operational conditions. Their robust construction enables safe operation at altitudes up to 1000 meters and high ambient humidity, making them a sound investment for both new and retrofit systems.

Efficient Cooling & Durable Design

Engineered with natural air-cooled technology, these chokes maintain optimal operating temperatures without the need for external cooling systems. With insulation class F or H, the chokes promise longevity and consistent performance in ambient temperatures ranging from -10C to 45C. The sturdy base plate mounting and low-noise operation further enhance safety and user comfort in busy industrial spaces.

FAQs of Power Factor Correction Chokes (PFC):

Q: How do Power Factor Correction (PFC) Chokes improve the efficiency of AC circuits?

A: PFC chokes enhance system efficiency by improving the power factor and filtering out harmonics in AC circuits. By regulating the inductive load, they minimize losses, ensuring that electrical power is used more effectively within industrial applications.Q: What is the process for installing these chokes in electrical panels or capacitor banks?

A: Installation is straightforward using the base plate mounting system. The chokes are connected via screw terminals for secure electrical contact, and their compact size allows for customizable panel integration. Ensure the system is de-energized during installation and follow IS 5553/IEC60726 standards for safety.Q: When should I use copper versus aluminum winding material for the PFC chokes?

A: Copper windings are standard for superior conductivity and long-term reliability. However, aluminum winding is an optional choice if weight or budget constraints are significant. Both materials provide reliable performance, but copper offers lower resistance and higher durability in most scenarios.Q: Where are these PFC chokes best applied for optimal performance?

A: These chokes are ideal for industrial applications within electrical panels, capacitor banks, and dedicated power factor correction systems, especially where three-phase 415V AC power supplies are utilized. They perform reliably in environments with up to 95% relative humidity and at altitudes up to 1000 meters.Q: What benefits do the insulation classes F and H provide?

A: Insulation classes F and H ensure the chokes can withstand higher operating temperatures, improving longevity and safety. Class F is suitable for most industrial settings, while class H is preferred where higher temperatures or severe overloads may occur.Q: How does the natural air-cooled design contribute to the chokes performance and reliability?

A: The natural air-cooled design eliminates the need for external cooling systems, reducing maintenance and operational costs. This ensures continuous and quiet operation even in enclosed spaces, maintaining a noise level below 55 dB at one meter.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inductor and Chokes Category

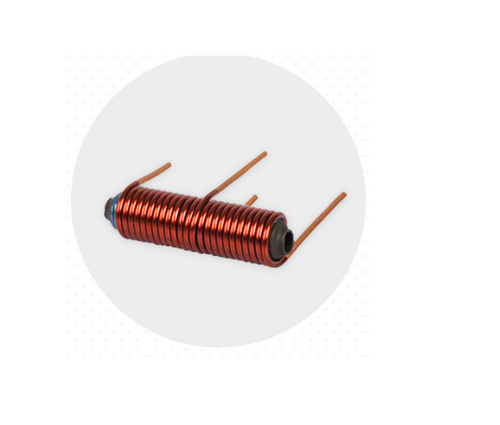

Rod Core - Drum Core Inductor

Price Range 80.00 - 300.00 INR / Piece

Minimum Order Quantity : 2000 Pieces

Power Supply : Not Applicable (Passive Component)

Product Type : Rod Core Drum Core Inductor

Weight : Approx. 13g (varies on size)

Drum Core Inductor

Price 75 INR / Piece

Minimum Order Quantity : 2000 Pieces

Power Supply : DC

Product Type : Drum Core Inductor

Weight : Approx. 1g to 10g

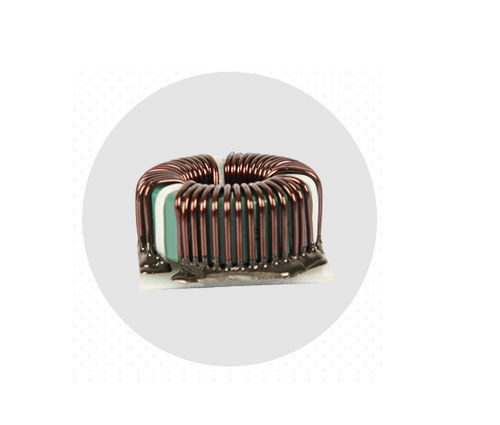

CMC Choke

Price 500 INR / Piece

Minimum Order Quantity : 500 Pieces

Power Supply : AC

Product Type : Common Mode Choke

Weight : Approx. 150g

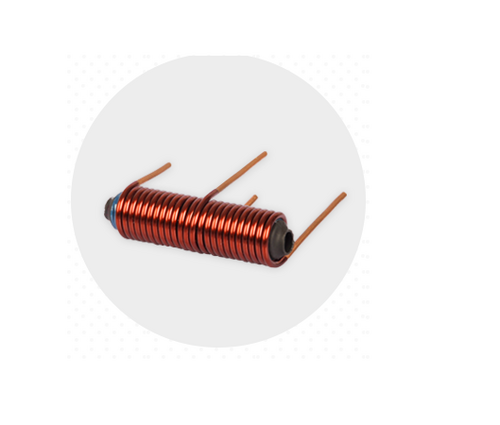

Rod Core Inductor

Price 75 INR / Piece

Minimum Order Quantity : 2000 Pieces

Power Supply : AC/DC

Product Type : Rod Core Inductor

Weight : Approx. 5 g

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS