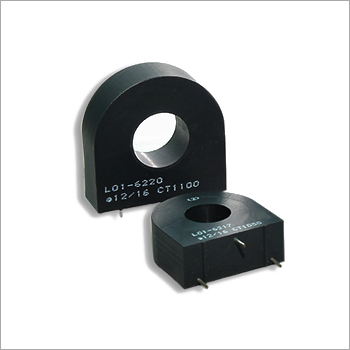

PCB Mountable Current Transformer

Price 00 INR/ Piece

PCB Mountable Current Transformer Specification

- Coil Material

- Electrolytic Copper

- Standard

- IS 2705 / IEC 61869-2

- Load Loss

- <0.5 Watt

- Low Voltage

- 1kV/1 min (Dielectric strength)

- Capacity

- 0.5 VA to 5 VA (Depending on model)

- Cooling Type

- Air cooled (Passive)

- Dimension (L*W*H)

- 16mm x 13mm x 19mm (Typical for PCB type)

- High Voltage

- 4kV/1 min (Impulse test)

- Operating Temperature

- -25C to +70C

- Rated Voltage

- Up to 660V (Primary to secondary insulation rating)

- Product Type

- PCB Mountable Current Transformer

- Material

- Ferrite Core with High-Quality Copper Winding

- Output

- 5A/1A Secondary Output (Standard options)

- Frequency (MHz)

- 50-60 Hz (Standard Application); up to 200 kHz for specialized models

- Efficiency

- Above 95%

- Phase

- Single Phase

- Usage

- PCB Mounting, Current Sensing, Signal Isolation

- Coil Structure

- Toroidal/Encapsulated

- Coil Number

- Single

- Power Scope

- 10 VA to 30 VA (Typical)

- Weight

- Approx. 30-50 grams

PCB Mountable Current Transformer Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- GT Standard or Customized

- Main Domestic Market

- All India

About PCB Mountable Current Transformer

Engineered for Versatile PCB Integration

Designed specifically for PCB mounting with 2 to 4 solderable pins, this current transformer suits a variety of board layouts and electrical requirements. The compact case allows easy installation within limited spaces, while the flame-retardant housing offers added safety in demanding environments. Each unit is clearly marked with laser or inkjet per part number and ratings, providing straightforward identification for assembly and maintenance.

Reliable Performance in Challenging Conditions

This transformer excels in operational stability, maintaining accuracy in humidity up to 95% RH (non-condensing) and temperatures ranging from -25C to +70C. Its strong dielectric and impulse voltage ratings (up to 4kV) ensure solid insulation between primary and secondary windings. With efficiency levels above 95% and low load loss (<0.5W), it delivers consistent, energy-efficient performance for precise current measurement.

Adherence to Global Quality and Safety Standards

Manufactured in accordance with IS 2705 and IEC 61869-2, this transformer guarantees high accuracy and long-term reliability. RoHS compliance underscores its commitment to environmental safety, while Class 0.5 and 1.0 accuracy grades make it suitable for industrial, commercial, and utility applications. Superior material choices including electrolytic copper windings and flame-retardant plastics further enhance operational integrity and durability.

FAQs of PCB Mountable Current Transformer:

Q: How do I mount this current transformer onto a PCB?

A: This current transformer is specifically designed for PCB mounting with solderable pins (2 to 4, depending on the model). Simply insert the pins into the designated holes on the circuit board, ensuring proper alignment, and solder them securely to maintain reliable electrical and mechanical connection.Q: What are the main applications for this PCB mountable current transformer?

A: Common applications include energy meters, current measurement circuits, relay sensing, signal isolation, overcurrent protection, and various monitoring systems. It is suitable for both general and specialized usage within energy management, industrial automation, and power quality equipment.Q: When should I choose Class 0.5 or Class 1.0 accuracy for my system?

A: Select Class 0.5 when precise current measurement is essential, such as in billing and sensitive metering devices. Class 1.0 is suitable for monitoring, control, and protection where highbut not the highestaccuracy suffices. Both classes adhere to IS/IEC standards and offer reliable performance.Q: Where can this current transformer be used considering environmental factors?

A: This product can be installed in environments with humidity up to 95% RH (non-condensing) and operating temperatures between -25C and +70C. The flame-retardant case and robust insulation make it safe for use in standard industrial and commercial electrical panels.Q: What is the process for customizing the primary current range or secondary resistance?

A: Customization is available for primary current ranges (1A50A) and secondary resistance (10500 Ohms). Consult the manufacturer or supplier to discuss your specific technical requirements, after which the appropriate model will be configured and manufactured to your applications needs.Q: How does this transformer benefit PCB designers and manufacturers?

A: The compact design, high efficiency (>95%), and robust material selection (flame-retardant plastic, ferrite core, electrolytic copper windings) simplify integration into PCB layouts. The units reliability, RoHS compliance, and adherence to global standards reduce maintenance and enhance product safety.Q: What are the standards and certifications observed by this current transformer?

A: This transformer is manufactured in alignment with IS 2705 and IEC 61869-2 standards. Its case material is UL94 V-0 certified for flame retardancy, and it is fully RoHS compliant, ensuring adherence to international safety and environmental guidelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Current Transformer Category

PCB Mount CT

Price 70 INR / Piece

Minimum Order Quantity : 500 Pieces

Usage : Current Sensing in PCB Mount Applications

Material : Epoxy Encapsulated, Copper Winding

Coil Structure : Other, Toroidal Core

Coil Material : Other , HighQuality Copper

HF PCB Mountable Current Transformer

Minimum Order Quantity : 1000 Pieces

Usage : Current Sensing in PCB Circuits

Material : Ferrite Core, Copper Winding, Flame Retardant Epoxy Casing

Coil Structure : Toroidal

Coil Material : Other , Enameled Copper Wire

PCB Current Transformer

Price 70 INR / Piece

Minimum Order Quantity : 1000 Pieces

Usage : PCB current sensing and monitoring applications

Material : Ferrite core with insulated copper wire

Coil Structure : Toroidal

Coil Material : Other , Enameled Copper Wire

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS